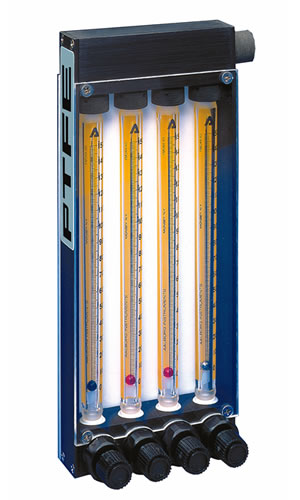

model Tx multi flow tube PTFE metersmodel Tx multi flow tube PTFE metersModel Tx Multiple Tube PTFE-Glass flow meters combine the convenience of multiple tube meters with the unique design features of single tube PTFE-Glass flow meters. These meters are available with the same interchangeable 65mm or 150mm glass flow tubes used in single tube designs and they are available with or without built-in PTFE needle valves. Wetted inert components are surrounded by structurally rigid anodized aluminum. The resultant design represents a unique combination of a rugged mechanically rigid frame and chemically inert wetted parts.They are ideal for applications where several streams of corrosive gases or liquids are to be metered in individual channels or as a controlled mixer in manifolded models. Flow tubes for these variable area flow meters (rotameters) are available with two types of scales, suitable for different types of applications DIRECT READING SCALES Direct reading scales are indicating flow rates of liquids and gases,in engineering units such as [mL/min], standard cubic feet per hour [scfh] etc. Such scales are designed exclusively for a specific gas or liquid at a given set of pressure and temperature parameters, and are valid for the associated units of flow only. The convenience of direct reading scale designs should be weighed against the resultant limitations of applicability. Generally, direct reading scales are most suited to OEM applications. UNIVERSAL MILLIMETER (CORRELATED) SCALES Millimeter scales indicate the vertical position of the spherical float within the metering tube as the flow increases or decreases. It is necessary to use flow tables or graphs supplied, to correlate float referenced readings with actual volumetric flow rates. Alternatively the flow tables and graphs can be found using our online Flow-Tube Calibration Data Library by looking up your flow tube part number. The advantage of Universal type scales is the ability to utilize the use of a given flow meter for a great number of different fluids at diverse pressure and temperature conditions, generally preferred in applications in laboratories, etc. BUILT-IN VALVES Meters are available with built-in needle valves (CVT™ ), high precision metering valves (HRT™) with “non-rising stems”, or with no valves. The higher cost of HRT™ valves is justified whenever high sensitivity control and resolution are desirable particularly in conjunction with metering tubes of very low flowrates. When meters with valves are ordered the valve cartridges are installed at the inlet. For vacuum service it is recommended that meters are ordered with valves at the outlet.

|